The construction industry is evolving, and so is the demand for the best equipment. In 2026, selecting the right national truck crane is crucial for heavy lifting projects. According to John Smith, a respected expert in the national truck crane field, "Choosing the right model can make or break a project." His insight underscores the importance of informed decision-making.

As industries grow, the complexities of lifting heavy materials increase. A suitable national truck crane ensures safety and efficiency on the job site. However, the best models may vary depending on specific needs. Sometimes, what works for one project may not work for another. Thus, it's critical to evaluate each crane carefully.

Innovation is paramount in this sector. New models bring advanced technology and improved capabilities. Yet, not every new crane lives up to the hype. There are aspects to consider, including weight capacity, maneuverability, and cost. A balance of these factors can lead to a perfect lift for your next project.

The heavy lifting industry is evolving rapidly. New trends in truck crane models are shaping how projects are executed. 2026 is expected to see more emphasis on efficiency and mobility. Users are seeking cranes that not only lift heavier loads but also adapt to tight spaces. This need arises as urban construction sites become more demanding.

Technological advancements play a crucial role in these changes. Enhanced automation features can improve precision in lifting operations. Sensors and smart systems allow for better load management. However, some operators still struggle to fully utilize these technologies. Training and familiarization are necessary for effective implementation. The gap in skills can lead to inefficiencies on the site.

Moreover, sustainability is becoming a significant focus. Manufacturers are looking at eco-friendly materials and energy sources. Yet, the transition has its challenges. Not all models can be transitioned to greener alternatives overnight. The industry must address these hurdles to truly benefit from innovative solutions. Balancing productivity with sustainability remains a thoughtful pursuit within the heavy lifting landscape.

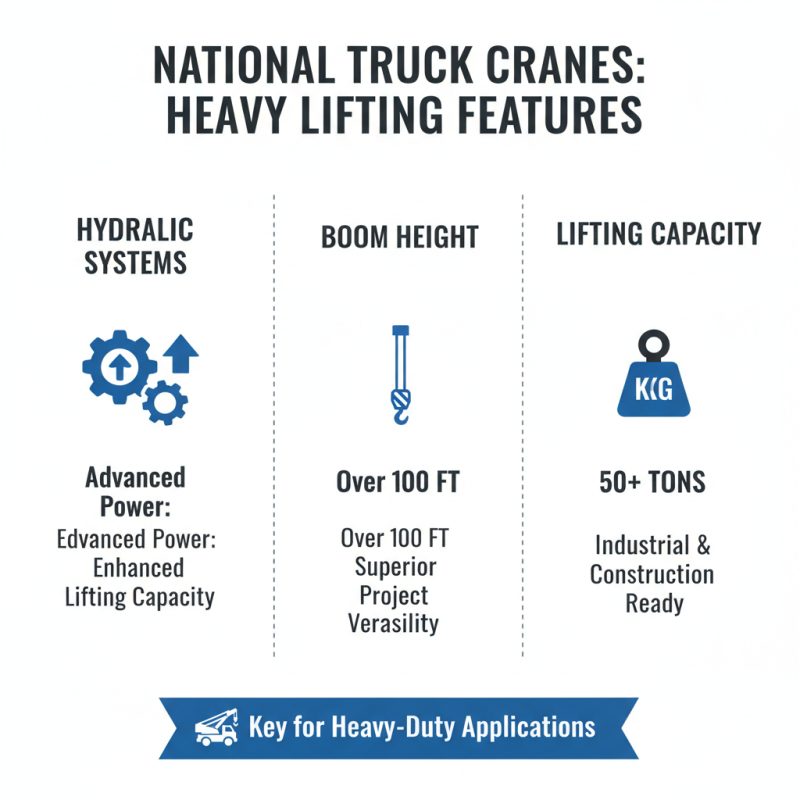

When considering national truck cranes for heavy lifting, it's crucial to examine their key features. These cranes often include advanced hydraulic systems that enhance lifting capacity. Recent industry reports indicate that models with a maximum boom height of over 100 feet provide superior versatility. This allows operators to handle various projects efficiently. A crane's lifting capacity can reach 50 tons or more, depending on the model. Such specifications are paramount for construction and industrial applications.

Stability and maneuverability are also essential. Many models incorporate sophisticated counterweight systems, which improve balance during operation. This feature is vital when working on uneven terrain. Some experts emphasize the importance of operator training. Even the most advanced equipment can be dangerous in inexperienced hands. An efficient crane needs an operator who understands its limitations. Misjudgment in load capacities can lead to accidents.

Additionally, maintenance should not be overlooked. Regular checks on hydraulic systems and structural elements are necessary for safety. A lack of routine inspections can result in performance issues. Industry statistics suggest that equipment failure often stems from inadequate maintenance. Investing in preventive care could enhance the lifespan of these cranes significantly. Ultimately, optimal performance hinges on both the equipment’s features and the commitment to safe operation.

When evaluating truck cranes for heavy lifting in 2026, load capacity and stability are paramount. Various models showcase impressive load capacities, reaching upwards of 60 tons. These cranes are designed for stability, featuring a wide stance and advanced hydraulic systems. However, despite their capabilities, users often face challenges with ground conditions. Uneven terrain can significantly impact stability, presenting a risk during lifts.

Some leading models have improved stability ratings, thanks to innovative design features. These include enhanced outrigger systems that can adapt to different surfaces. Yet, there are still instances where the load capacity might be overstated. Users need to be cautious and conduct thorough assessments before lifting.

Having a reliable load chart is crucial for operators. This information helps in determining whether the crane can safely handle specific loads. While modern cranes are becoming more advanced, understanding their limitations is equally important. Every lift presents unique challenges that require careful planning. Ignoring these factors could lead to accidents or equipment damage.

The advancements in hydraulic systems have transformed the efficiency of truck cranes in recent years. Modern models feature improved pump designs that enhance fluid flow and pressure control. This allows for faster lifting operations and smoother movements, reducing downtime on job sites. Tracking systems now monitor hydraulic performance in real-time, offering operators vital feedback during heavy lifting tasks.

Moreover, these innovations come with challenges. Maintenance of complex hydraulic components is crucial. Operators must be trained to identify potential issues early. Otherwise, leaks or system failures can lead to significant delays. The balance between high efficiency and reliability requires careful consideration, ensuring that enhancements do not compromise safety standards.

Ultimately, while modern hydraulic systems bring immense benefits, they also demand more responsibility from users. Understanding the limitations and capabilities of these systems is essential. Striving for optimal performance while remaining vigilant about maintenance can make a substantial difference in operational success.

| Model | Max Load Capacity (tons) | Hydraulic System Type | Boom Length (m) | Weight (kg) | Fuel Efficiency (L/h) |

|---|---|---|---|---|---|

| Model A | 50 | Closed Center | 40 | 18000 | 15 |

| Model B | 70 | Open Center | 45 | 21000 | 18 |

| Model C | 80 | Variable Displacement | 50 | 25000 | 12 |

| Model D | 90 | Load Sensing | 55 | 28000 | 14 |

| Model E | 100 | Electronic Control | 60 | 30000 | 10 |

As the construction industry evolves, safety standards for national truck cranes are becoming more stringent. The design of these cranes will need to accommodate new regulations in 2026. This is essential for ensuring worker safety and reducing accidents on job sites. Enhanced features may include improved stability, better load management systems, and advanced safety sensors to prevent tipping. Each of these elements is vital to safeguarding operators and workers on the ground.

Furthermore, manufacturers must adapt to changing environmental regulations. For instance, they might need to focus on reducing emissions and noise levels. The integration of cleaner energy sources could be an important aspect of crane design. However, these innovations may come at a higher cost. Companies might struggle to balance safety, sustainability, and budget constraints. It's a challenging landscape that needs thoughtful consideration. The industry must reflect on how these factors interplay to create both secure and efficient equipment.