In the ever-evolving landscape of construction and heavy lifting, selecting the right equipment is crucial for ensuring efficiency and safety. A "truck with a crane" serves as a versatile solution for various lifting needs, combining mobility with powerful lifting capabilities. According to a recent industry report from the Construction Equipment Association, the demand for cranes mounted on trucks has increased by over 15% in the past year, reflecting a growing reliance on this indispensable equipment across multiple sectors.

Expert in the field, Dr. Michael Thompson, a noted engineering consultant, emphasizes the importance of making informed choices in this area. He states, “The right truck with a crane can dramatically enhance productivity on site while minimizing operational costs." This highlights the significance of understanding both the technical specifications of the cranes and the specific requirements of the tasks at hand. By taking the time to assess various models and their capabilities, businesses can ensure they invest in the most suitable equipment to meet their heavy lifting needs effectively.

As companies continue to navigate the challenges of larger and more complex projects, the integration of a truck with a crane is becoming not just a choice but a necessity. Proper selection can lead to significant improvements in operational efficiency and safety standards, setting the foundation for successful project execution.

When selecting the right truck fitted with a crane for heavy lifting tasks, it is essential to first evaluate your specific lifting requirements. Consider the weight of the loads you intend to lift, as well as their dimensions. Industry reports indicate that the average load capacity for truck-mounted cranes ranges from 14 tons to over 40 tons, but you must select a crane that not only handles the weight but also accommodates the load's center of gravity for optimal safety and efficiency. Understanding these specifications is crucial for preventing overloading and ensuring compliance with safety regulations.

Tips: Always calculate the total weight of the adjustable load and consider future lifting needs. Having a crane that can handle slightly more than your immediate requirements can provide flexibility for unexpected challenges.

In addition to load capacity, crane reach and hydraulic performance are pivotal in choosing the right truck. Most cranes offer a range of boom lengths, and a longer boom can allow for greater versatility on job sites with varying lift heights. According to the National Crane Safety Institute, proper selection means matching the boom length to the specific tasks you envision, reducing strain on the crane and enhancing operational efficiency. Evaluate the hydraulic capabilities and features that enhance stability, such as outriggers and counterweights, to ensure the crane can perform safely under varying conditions.

Tips: Prioritize features like variable reach and stability aids in cranes, as these can dramatically improve operational safety and efficiency, particularly in dynamic environments. Always consult the manufacturer's specifications to ensure the crane meets your lifting and performance needs.

When evaluating different types of trucks with crane capabilities, it is essential to consider the specific lifting requirements and the environment where the vehicle will operate. Trucks can vary greatly in terms of weight capacity, reach, and versatility, so assessing your needs is the first step. For instance, if your operations are often conducted in tight spaces, a truck with a smaller footprint and a crane with a compact design would be ideal. Conversely, if you require handling heavy loads over long distances or at higher elevations, opting for trucks with robust capabilities and higher lifting power is crucial.

Tips: Always check the truck's weight ratings and the crane's maximum lifting capacity. Match these specifications to the types of loads you will be handling. Additionally, consider the terrain your truck will typically navigate. If operations will take place in rugged or off-road conditions, select a truck designed for such environments, ensuring it has appropriate tires and suspension.

Another aspect to evaluate is the ease of operation and safety features. Advanced cranes come equipped with user-friendly controls and safety mechanisms to prevent accidents during lifting. It’s advisable to invest in training for operators to maximize efficiency and minimize risks. Regular maintenance and inspections of both the truck and crane ensure sustained performance over time.

When selecting a truck with a crane for heavy lifting requirements, assessing load capacity and stability is paramount. According to the Occupational Safety and Health Administration (OSHA), nearly 90% of crane accidents result from improper use or inadequately assessing load limits. Therefore, understanding the specific load capacity rating of the truck and crane combination is essential to ensure safe operational practices. Load capacity is typically defined by the crane's manufacturer and should be strictly adhered to; exceeding this limit can lead to catastrophic failures.

Stability is another critical factor that must be evaluated. A 2022 report from the National Institute for Occupational Safety and Health (NIOSH) emphasized that cranes must have a low center of gravity and adequate outrigger positioning to prevent tipping. Operators should consider the surface conditions where the truck will be operating, as uneven or soft ground can significantly decrease stability. Furthermore, real-time assessment tools and load moment indicators are pivotal for maintaining safety. NIOSH data suggests that using these advanced technologies can reduce accidents by as much as 30%, underscoring the importance of integrating safety measures during operation and selection.

When selecting a truck equipped with a crane for heavy lifting, it’s crucial to consider the features and technologies of the crane itself, as these can significantly influence performance and efficiency. One of the primary features to evaluate is the crane's lifting capacity, which should align with the maximum weights you plan to handle. Consider cranes with variable reach capabilities, as these offer flexibility in maneuvering loads in tight spaces or when working at various heights.

Modern cranes also incorporate advanced technologies that enhance performance. For example, load monitoring systems provide real-time data on lifting loads, reducing the risk of overloads and improving safety during operations. Additionally, some cranes come equipped with automated controls that facilitate smoother operation and reduce operator fatigue. Features such as stabilizer legs and outriggers enhance stability, allowing for safer lifting even on uneven terrain. By thoroughly assessing these features and technologies, you can select the right truck with a crane that meets your heavy lifting needs effectively and efficiently.

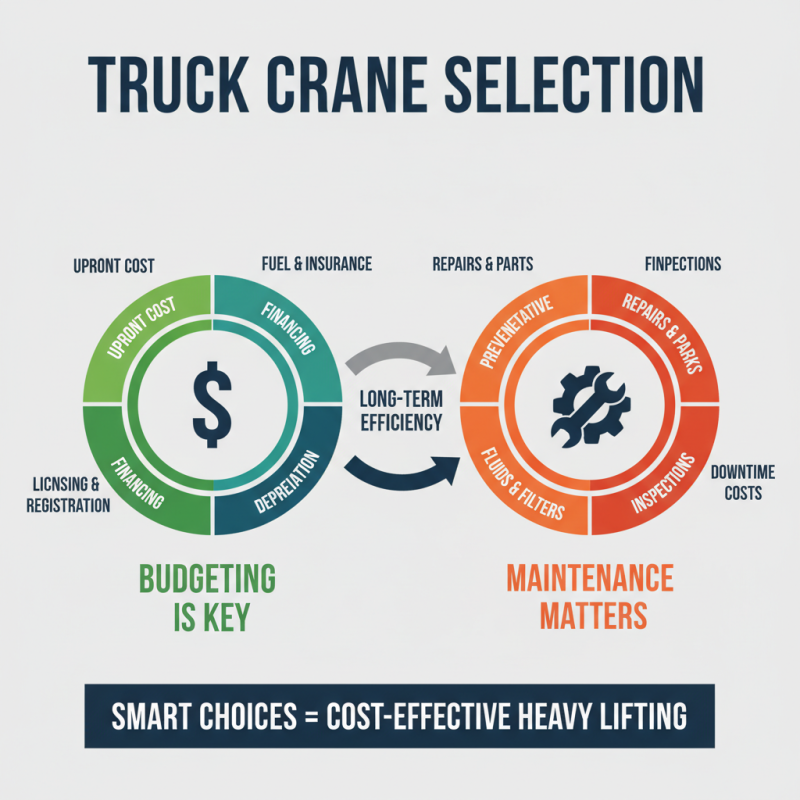

When selecting a truck with a crane, one must prioritize budgeting and maintenance considerations to ensure long-term efficiency and cost-effectiveness. Initially, it’s crucial to set a budget that encompasses both the upfront purchase price and the ongoing operational expenses. This includes fuel, insurance, and the costs associated with licensing and registration. It’s also important to factor in the potential need for financing, as well as the depreciation of the vehicle over time. By having a clear understanding of these financial aspects, you can make a more informed choice that aligns with your heavy lifting needs without overextending your resources.

Maintenance, on the other hand, plays a pivotal role in the operation of your truck and crane setup. Regular inspections and servicing are necessary to keep both the truck and crane in optimal working condition. This involves not only monitoring fluid levels and checking for mechanical issues but also adhering to manufacturer guidelines for maintenance schedules. Establishing a proactive maintenance plan will help prevent costly repairs down the line and ensure the safety of the equipment and its operators. Additionally, investing in quality parts and employing skilled technicians for repairs can significantly lower long-term costs and enhance the reliability of your lifting operations.