Selecting the right truck mounted crane can be a daunting task. The booming construction and logistics industries have driven demand for these versatile machines. According to a recent Freedonia Group report, the global crane market is expected to reach $45 billion by 2025. This growth signals an increasing reliance on truck mounted cranes across various sectors.

Understanding your specific needs is crucial. Factors such as lifting capacity, reach, and operational environment significantly influence your decision. Industry data indicates that over 60% of operators report a need for cranes with enhanced maneuverability. However, many still overlook critical details during their selection process, leading to inefficiencies.

Moreover, the complexity of available models can be overwhelming. Many buyers may prioritize price over performance, which can result in higher long-term costs. Identifying the right specifications and ensuring safety standards should not be compromised. This article will guide you through the essential considerations for choosing a truck mounted crane tailored to your unique requirements.

When exploring the types of truck-mounted cranes available, several key options stand out. These cranes are typically classified based on their lifting capacity, boom length, and the specific tasks they are designed for. Common categories include telescopic cranes, articulated cranes, and loader cranes. Each type brings unique advantages tailored to different applications. For example, telescopic cranes can extend to significant heights, making them ideal for construction sites. Articulated cranes offer flexibility, navigating tight spaces with ease.

Industry reports indicate that the demand for truck-mounted cranes is projected to grow by 5.2% annually through 2025. Companies are increasingly investing in advanced models featuring enhanced safety and performance metrics. However, choosing the right crane can still be challenging. It’s essential to assess the operational requirements, such as load capacity and work environment. Mistakes in this selection process can lead to inefficiencies or safety hazards.

Another consideration is the weight of the crane relative to the truck's ability to transport it. Overloading can not only damage the vehicle but also compromise safety during operations. Research highlights that improper equipment choice has historically resulted in up to 30% of job site accidents. This statistic underscores the importance of meticulous evaluation. Understanding these factors ensures that the selected crane meets both productivity and safety standards efficiently.

Choosing the right truck-mounted crane begins with clearly understanding your load capacity and reach requirements. Evaluate the maximum weight you need to lift. Consider the materials and their distribution. It's easy to underestimate the load during planning. A crane's stability can be compromised by excessive weight. Always double-check the weight specifications of your loads.

Next, assess the reach needed for your tasks. Think about the height and distance from the truck to the load. It's common to overlook how different angles can affect reach. For example, lifting a load over an obstacle can require greater reach than expected. Measure your site to avoid surprises. Consider the space constraints, as not all cranes can maneuver easily in tight places.

Don’t forget to reflect on your future needs. Will your projects grow in scale? Anticipating changes can guide your decision. Selecting a crane solely based on current tasks might lead to limitations. It’s important to balance present and future demands. Gather input from your team; their insights can reveal overlooked aspects. Keep these considerations in mind as you make your choice.

When choosing a truck mounted crane, safety features are paramount. It is vital to evaluate the safety features thoroughly. Look for models that include automatic shutoff systems and overload protection. These features can prevent accidents and protect both operators and workers on the ground.

Tips: Always check for the complying standards. Verify if the crane adheres to local safety regulations. Each region may have specific requirements that need to be met for safety compliance. This ensures the crane is suitable for your operating environment.

Consider the crane's stability indicators. They are essential for safe operation. If the crane lacks this feature, rethink your options. Operators should be trained to use these safety features effectively. Ignoring proper training can lead to avoidable mishaps. A well-trained operator can make a significant difference in safety outcomes.

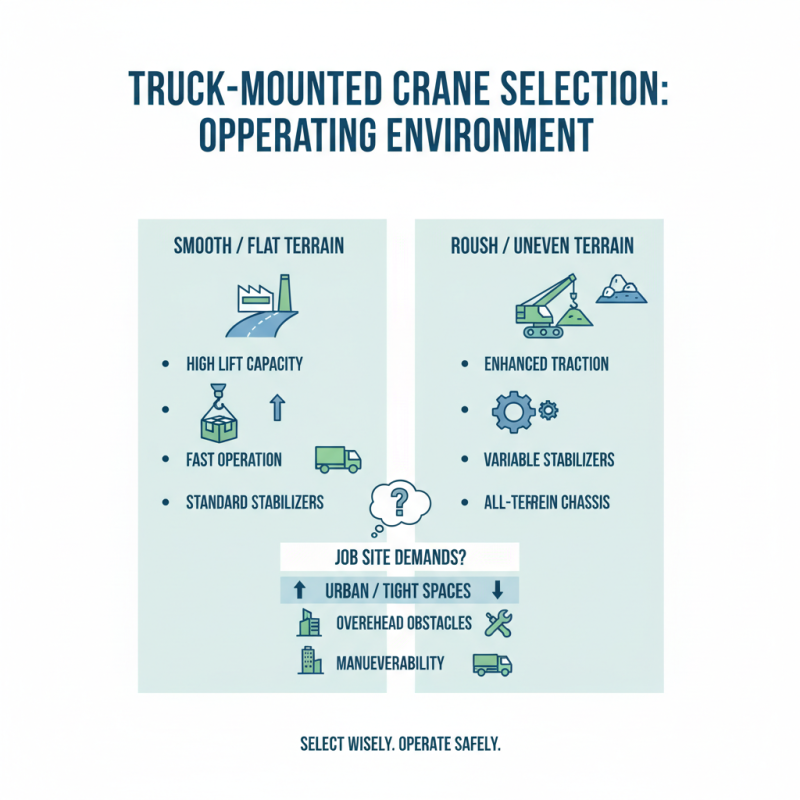

When selecting a truck-mounted crane, the operating environment plays a crucial role. A crane that operates well on a smooth, flat surface may struggle in rough terrain. Understanding the specific demands of your job site is essential. If you are working in an urban area, consider the height of buildings and overhead obstacles. Tight spaces may require a crane that can maneuver easily without compromising its lifting capacity.

Terrain also influences crane performance significantly. Soft ground can cause a truck-mounted crane to sink or tip over. Choose cranes equipped with stabilizers or outriggers for better support. If you are working in mountainous or uneven regions, a crane with all-terrain capabilities is critical. Some users overlook the impact of weather conditions. High winds or rain can limit what a crane can safely lift.

While it's tempting to choose a crane based only on capacity, this can be misguided. Lifting power is important, but stability and adaptability are equally valuable. Reflecting on the site’s needs before making a decision can save time and money. Researching terrain requirements and assessing potential challenges are necessary steps. Remember, a truck-mounted crane should be a reliable, safe tool to enhance productivity.

When choosing a truck mounted crane, budgeting is crucial. Understand the initial purchase price, but don't stop there. Include maintenance and operational costs in your calculations. Regular maintenance can prevent costly repairs later. Additionally, factor in fuel costs, as they can add up quickly.

Tip: Create a spreadsheet to track all costs. This will help you visualize your budget better. Don't forget to include training for operators. Well-trained staff can increase efficiency and reduce accidents.

Be mindful of resale value, too. A crane that holds its value can ease your financial burden. Evaluate your long-term needs. Sometimes, it’s worth spending a bit more for reliability. Research thoroughly and think about your specific use cases. Mistakes can be costly, so take time to plan wisely.