Choosing the right large mobile crane for your project can be challenging. The selection process involves various factors. Size, capacity, and features are essential considerations.

When assessing large mobile cranes, the project's specific needs must be evaluated. Think about the weight of the materials you'll lift. Consider the height and reach necessary for your tasks. Each crane model offers different advantages. You must align these with your project requirement.

Moreover, it’s crucial to account for site conditions. Some cranes perform better on uneven ground. Others may need additional support or stabilization. Reflect on these points to ensure the best choice. Selecting a large mobile crane can affect the project's overall success. It's a critical decision that warrants careful thought.

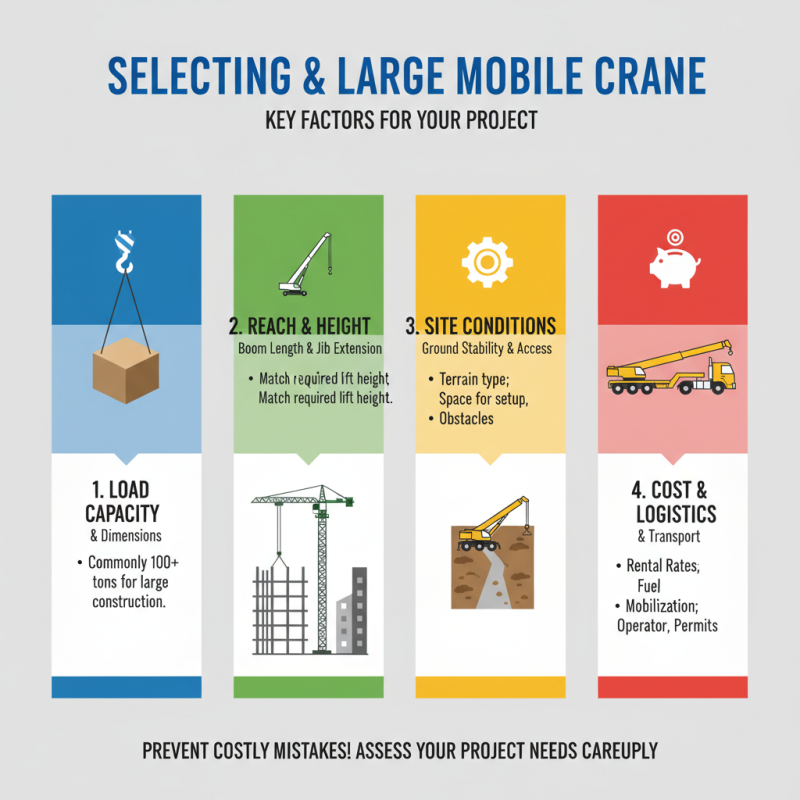

When selecting a large mobile crane for your project, several key factors should be evaluated. One important aspect is load capacity. According to industry reports, cranes with a capacity of 100 tons or more are increasingly common in large-scale construction. Understanding your specific load requirements can prevent costly mistakes. Not every crane can handle the weight and dimensions of your materials.

Stability is another critical consideration. A crane must be stable under heavy loads and on uneven ground. The National Commission for the Certification of Crane Operators emphasizes that stability failures are a leading cause of accidents. Ensuring proper rigging and using outriggers can enhance the crane’s stability significantly. Many projects underestimate the impact of terrain, leading to unsafe setups.

Mobility is crucial as well. Choose a crane that can easily move around your job site. A crane with better maneuverability can save time and resources during operation. Additionally, the crane's reach should match your project's height and distance needs. Reviewing site plans and logistics is essential in this phase. This aspect often gets overlooked, resulting in inefficiencies.

Choosing the right crane begins with understanding load capacity. Load capacity defines the maximum weight a crane can lift. For substantial projects, this number is paramount. Industry studies indicate that around 20% of crane accidents occur due to overloading. This statistic highlights the critical need for accuracy in load assessments.

Evaluate specific project requirements. Are you lifting steel beams or heavy machinery? Different materials produce different weight distributions. A crane’s stability is affected by load placement. Research shows that 40% of operators miscalculate load centers. Such errors can lead to dangerous situations. It's essential to double-check these figures.

Additionally, consider the crane's reach and height capabilities. A crane that can lift a heavy load may still be inadequate for tall structures. Many construction projects face delays due to improper crane selection. This often leads to increased costs and safety risks. Accurate crane choice impacts work efficiency considerably. Hence, thorough planning is necessary to ensure a successful lift.

When selecting a large mobile crane, understanding crane configurations is vital. There are various types, each suited for specific applications. For example, all-terrain cranes excel in rough terrains. They combine mobility with lifting power. Their versatility makes them popular in construction and oilfield projects.

Consider crawler cranes when stability is a priority. These cranes distribute weight over a large area. They work well on soft ground but lack mobility on rough surfaces. Rough-terrain cranes are another option; they’re designed for off-road conditions. However, their lifting capacity can be limited compared to other models.

Tips: Always match the crane type to the project requirements. Assess the site conditions and load specifications. Weight distribution, boom length, and lifting height are crucial. Keep in mind that larger capacity may not always be better. Sometimes, a smaller, more flexible crane is ideal for tight spaces.

Reviewing industry reports, over 30% of crane accidents are linked to improper configuration. Therefore, ensuring the right crane type can improve safety and efficiency. Taking the time to evaluate configurations can save resources and prevent mishaps.

Choosing the right large mobile crane for a project requires careful consideration of site conditions. Among these, terrain and accessibility play crucial roles. A report from the Construction Industry Institute indicates that 45% of project delays stem from inadequately evaluating site conditions. This highlights why a thorough assessment is critical.

When assessing terrain, factors like slope, ground type, and stability matter. Soft ground can limit the weight a crane can safely bear. A 2021 analysis found that using cranes on unstable terrain can lead to accidents, increasing costs by up to 30%. Access routes must also be evaluated. Narrow paths or low bridges can hinder crane transportation. Data suggest that 70% of site accidents involve issues related to accessibility, underscoring the need for detailed planning.

Moreover, project managers often underestimate the impact of weather on mobile cranes. High winds or rain can affect crane stability. Engineers should build in contingency plans for unpredictable weather patterns. Ignoring these elements can lead to safety incidents and delays. An informed decision involves not just selecting the right equipment, but understanding the site intimately. The complexity of site evaluation means there is always room for improvement in planning methods.

When it comes to mobile crane operations, safety standards are paramount. The Occupational Safety and Health Administration (OSHA) outlines specific regulations to ensure safe practices. In the United States, there are around 2,300 crane-related injuries annually, highlighting the importance of compliance. Each operator must maintain proper certifications and adhere to manufacturer guidelines. Regular inspections are also essential to avoid equipment failure.

Moreover, the American National Standards Institute (ANSI) sets forth standards for crane safety. They emphasize the importance of operator training and awareness of load capacities. It is crucial that operators can identify hazardous conditions before they cause accidents. The industry aims to reduce the incidence of crane accidents by 20% in the next five years through improved training protocols.

Inadequate training can lead to mistakes, raising the question of responsibility. Often, operators face pressure to perform quickly. This can result in overlooking safety checks. Data shows that 40% of crane incidents relate to human error. Therefore, cultivating a culture that prioritizes safety over speed is a significant challenge in the industry. Each project should foster a space for reflection and improvement regarding safety practices.

| Crane Type | Max Load Capacity (tons) | Operating Radius (m) | Height (m) | Safety Standard | Regulatory Compliance |

|---|---|---|---|---|---|

| Boom Crane | 100 | 35 | 60 | ANSI B30.3 | OSHA |

| All Terrain Crane | 120 | 40 | 55 | EN 13000 | CE Marking |

| Crawler Crane | 150 | 50 | 70 | ISO 4301 | ASME B30.5 |

| Truck Mounted Crane | 80 | 30 | 50 | CSA Z150 | DOT Regulations |