When embarking on a new construction or lifting project, selecting the appropriate equipment is crucial for ensuring efficiency and safety. Among the various options available, a mobile lift crane stands out as a versatile solution that can adapt to different job site conditions and demands. Industry expert John Smith, a seasoned construction engineer with over 20 years of experience, emphasizes the importance of this choice: "The right mobile lift crane can significantly enhance productivity while minimizing risks on site."

As projects vary in scope and requirements, understanding the different features and capabilities of mobile lift cranes becomes essential for making an informed decision. From load capacity to maneuverability, each factor plays a vital role in determining the most suitable crane for specific tasks. Engaging with experts and doing thorough research can provide invaluable insights into selecting the best mobile lift crane to meet your project needs effectively.

Ultimately, choosing the right mobile lift crane not only impacts operational efficiency but also ensures the safety of the crew and equipment involved. By considering expert advice and evaluating various options, project managers can navigate the complexities of crane selection with confidence, paving the way for successful project execution.

When embarking on a project that requires a mobile lift crane, it's essential to understand the fundamentals of these versatile machines. Mobile lift cranes, designed for ease of transportation and rapid deployment, are equipped with various features that cater to different lifting tasks. They come in multiple configurations, including telescopic and rough terrain options, each suited for specific environments and load capacities. Knowing the basics, such as the lifting height, weight limits, and operating radius, will give you a clearer idea of which type of crane is best suited for your project's demands.

Another crucial aspect to consider is the mobility and stability of the crane. Many mobile lift cranes are designed to operate in challenging terrains, making them ideal for construction sites, industrial applications, or other remote locations. Operators must evaluate the ground conditions and ensure the crane has adequate support and leveling capabilities, as this directly affects safety and performance. By understanding these essential elements, you can make an informed decision that align with your project's requirements and ensures efficiency throughout the lifting process.

When selecting a mobile lift crane for your project, understanding the specific requirements is crucial. Begin by assessing the nature of the project, including the types of materials to be lifted, their weight, and the lifting height. This assessment will help you determine the necessary specifications for the crane, such as its lifting capacity and reach. Consider whether the project environment presents any unique challenges, such as limited space, uneven terrain, or proximity to other structures, which might influence the choice of crane type and configuration.

Additionally, take into account the duration of the project and the frequency of use. If the crane will be used for extended periods or multiple lifts, investing in a more robust model may be beneficial to ensure reliability and efficiency. Moreover, evaluate the mobility requirements—whether the crane needs to navigate tight spaces or if it will be primarily stationed on a construction site. These factors will guide you in selecting a mobile lift crane that not only meets the operational demands but also aligns with safety and compliance standards. Understanding your project requirements thoroughly will lead to an informed decision that optimizes performance and productivity.

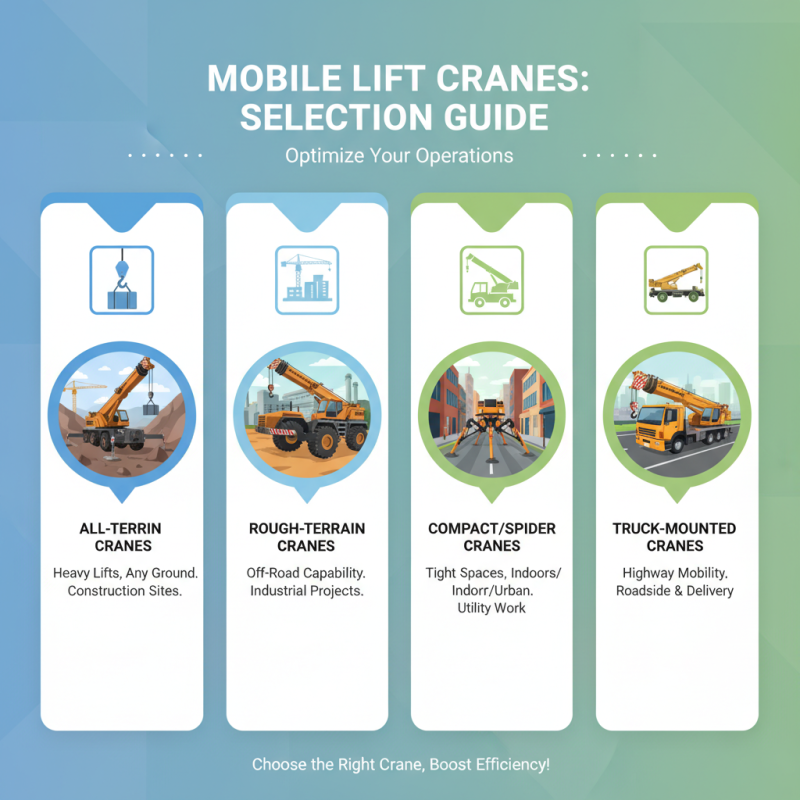

When selecting the right mobile lift crane for a project, it is crucial to evaluate the various types and their specific functions. Mobile lift cranes come in a variety of configurations, each designed to fulfill different operational needs. For instance, some cranes are better suited for heavy lifting in construction sites, while others are designed for maneuverability in tight spaces, such as urban environments. Understanding these distinctions can significantly enhance the efficiency of your operations.

Tips: Always assess the load capacity and reach required for your project. If the operation involves lifting materials at significant heights, prioritize cranes with a higher reach capability. Additionally, consider the terrain and workspace. Cranes with all-terrain features can navigate rough surfaces, which is essential for outdoor projects.

It's also important to look into the control mechanisms of the crane. Some operators may prefer electronic controls for precision, while others may favor hydraulic systems for their responsiveness. Always ensure that the crane's operation aligns with the skill level of your team. Training and familiarity with the crane's functions can prevent accidents and improve productivity on the job site.

When selecting a mobile lift crane for your project, the first factor to consider is the lifting capacity. It's essential to determine the maximum weight that the crane needs to lift and to ensure that the chosen model can safely handle this load. Different projects will require varying capacities based on materials and equipment, making it crucial to match the lift crane's specifications with your demands. Additionally, consider the height requirements of your project, as cranes come with different maximum height capabilities that must align with your worksite needs.

Another important aspect to evaluate is the crane's mobility and stability. The terrain of the job site can significantly influence a crane's performance; therefore, selecting a model that can navigate the specific conditions—be it rough, uneven ground or tight spaces—is vital. Look for features such as outriggers or stabilizers that enhance balance and prevent tipping during operation. Furthermore, consider the ease of setup and the speed at which the crane can be deployed, as efficiency can impact overall productivity on the job. Taking these factors into account will ensure that you make an informed decision, leading to a successful project outcome.

| Factor | Description | Importance Level | Examples |

|---|---|---|---|

| Capacity | The maximum weight the crane can lift. | High | 10 tons, 20 tons, etc. |

| Height | Maximum lifting height for the crane. | Medium | 30 ft, 50 ft, etc. |

| Mobility | Ease of movement on job sites. | High | Wheeled vs. tracked models. |

| Stability | Factors that prevent tipping during operation. | High | Outriggers, counterweights. |

| Reach | Horizontal distance the crane can extend. | Medium | Reach of 30 ft, 60 ft, etc. |

| Terrain Type | Type of terrain where the crane will operate. | High | Rough, clear, uneven. |

| Power Source | Type of power used to operate the crane. | Medium | Diesel, electric, hybrid. |

In the construction and industrial sectors, mobile lift cranes play a pivotal role in enhancing productivity and efficiency. However, the safe operation of these cranes is paramount, necessitating adherence to stringent safety and compliance standards. According to the Occupational Safety and Health Administration (OSHA) regulations, operators must be trained and certified, ensuring they are equipped to handle potential hazards associated with lifting operations. Furthermore, the American National Standards Institute (ANSI) provides guidelines on design, maintenance, and operation that industry professionals must follow. A study from the National Institute for Occupational Safety and Health (NIOSH) highlights that nearly 50% of crane-related accidents can be attributed to operator error, underscoring the importance of proper training and compliance with safety protocols.

Moreover, regular inspections and maintenance of mobile lift cranes are crucial in minimizing risks. OSHA mandates that cranes undergo routine checks to ensure they comply with safety standards. According to the Crane Safety Study, about 70% of crane incidents involve equipment failure due to inadequate maintenance, reinforcing the necessity of adhering to compliance guidelines. Additionally, employing technology such as load monitoring systems and operator-assistance features can enhance safety during crane operations. As the industry continues to evolve, organizations must prioritize safety training and remain vigilant in compliance efforts to protect workers and improve operational efficiency.