Steel cranes play a pivotal role in modern construction and industrial projects, providing the necessary lifting capabilities to handle heavy materials efficiently and safely. According to a report by the American Institute of Steel Construction, the demand for steel cranes is projected to increase by 12% over the next five years, driven by the growth in infrastructure development and the booming construction sector. These powerful machines are essential for ensuring that large-scale projects are completed on time and within budget, significantly reducing manual labor and enhancing workplace safety.

As industry expert John Smith, a leading structural engineer at the Steel Construction Society, aptly noted, "Steel cranes are not just tools; they are the backbone of any construction site, enabling us to lift heavier loads with precision and reliability." This sentiment underscores the importance of steel cranes in not only streamlining operations but also in advancing overall project efficiency. With advancements in technology, modern steel cranes are equipped with innovative features that enhance their performance and safety, further solidifying their indispensable role in the construction and industrial landscape. As we delve deeper into the reasons behind their necessity, it becomes clear that steel cranes are integral to meeting the challenges of today’s ambitious construction goals.

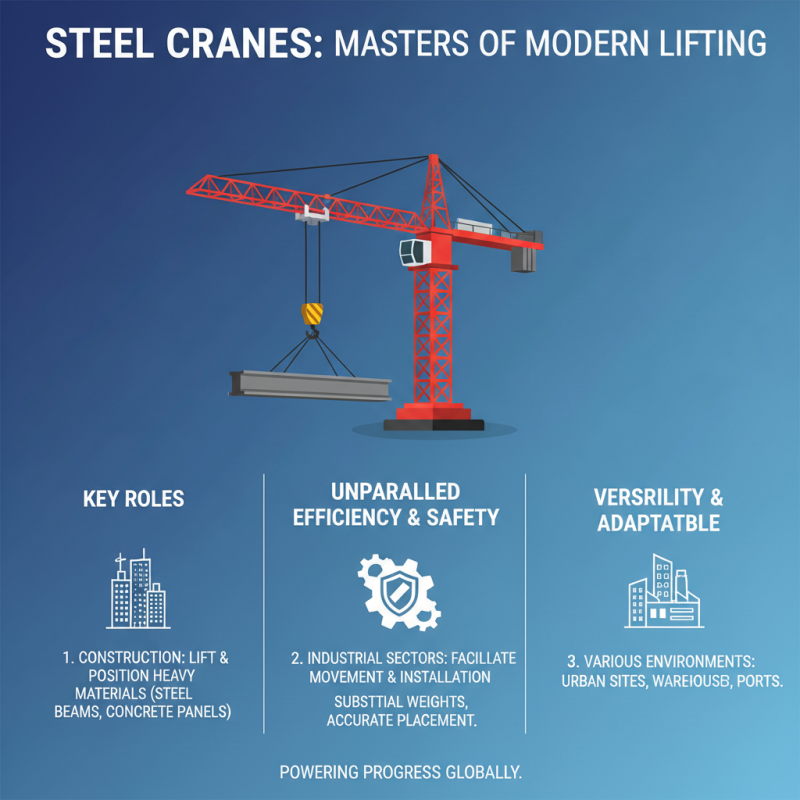

Steel cranes play a pivotal role in modern construction and industrial sectors, facilitating the movement and installation of heavy materials with unparalleled efficiency and safety. These robust machines are engineered to lift substantial weights, making them indispensable on construction sites where large components such as steel beams, concrete panels, and heavy machinery need to be positioned accurately. Moreover, the versatility of steel cranes allows them to operate in various environments, from urban settings with tight spaces to expansive industrial warehouses, enhancing their utility across different projects.

In addition to their lifting capabilities, steel cranes contribute to improved safety standards on job sites. By leveraging advanced technology, such as remote control systems and load monitoring, operators can execute complex maneuvers while minimizing the risk of accidents. This is particularly crucial in high-stakes environments where precision is vital. Furthermore, the presence of steel cranes reduces the physical demands on workers, decreasing fatigue and the likelihood of injuries associated with manual lifting. Therefore, as construction and industrial projects continue to evolve, the significance of steel cranes in ensuring operational efficiency and worker safety remains undeniable.

Steel cranes are indispensable tools in the construction and industrial sectors, primarily due to their robust performance and reliability. According to a report by the International Heavy Equipment Association, steel cranes are known to have a lifting capacity exceeding 1,000 tons, making them ideal for handling heavy loads that other materials cannot manage efficiently. This immense strength allows for the successful completion of large-scale projects, reducing downtime and increasing overall productivity.

In addition to their impressive lifting capabilities, steel cranes exhibit superior durability compared to their counterparts made from aluminum or other materials. A study published in the Journal of Construction Engineering and Management indicates that steel cranes can withstand severe weather conditions and last up to 50% longer under strenuous operational demands. Their resistance to corrosion and fatigue further enhances their lifespan, offering significant cost savings in terms of maintenance and replacement. With these advantages, the deployment of steel cranes in various construction and industrial applications ensures that projects are completed safely and efficiently, reinforcing their critical role in modern engineering.

The construction industry has witnessed significant growth in recent years, with steel cranes playing a pivotal role in this expansion. Industry statistics indicate that the demand for steel cranes has surged alongside the increasing number of infrastructure projects globally. According to recent reports, the construction market is projected to grow substantially, with steel cranes accounting for a sizable portion of the equipment utilized. Their strength, durability, and versatility make them indispensable in lifting heavy materials and enhancing operational efficiency on job sites.

As urbanization accelerates and new projects emerge, the reliance on steel cranes is becoming more pronounced. The statistics reveal not only a rise in the quantity of construction projects but also an uptick in investments directed towards advanced crane technologies. This trend highlights the industry’s commitment to improving safety and efficiency, as modern steel cranes are equipped with intelligent systems that optimize load handling and reduce the risk of accidents. The growth of steel cranes in construction signifies a broader shift towards adopting innovative solutions that can meet the challenges of complex projects in a dynamic market.

| Year | Market Size (USD Billion) | Growth Rate (%) | Key Application Sectors |

|---|---|---|---|

| 2018 | 5.0 | 4.5 | Construction, Shipping, Manufacturing |

| 2019 | 5.5 | 5.0 | Construction, Oil & Gas, Heavy Machinery |

| 2020 | 6.0 | 5.5 | Infrastructure, Manufacturing, Logistics |

| 2021 | 6.8 | 6.5 | Construction, Mining, Demolition |

| 2022 | 7.5 | 7.0 | Construction, Renewable Energy, Heavy Lifting |

| 2023 | 8.3 | 10.7 | Industrial, Transportation, Infrastructure |

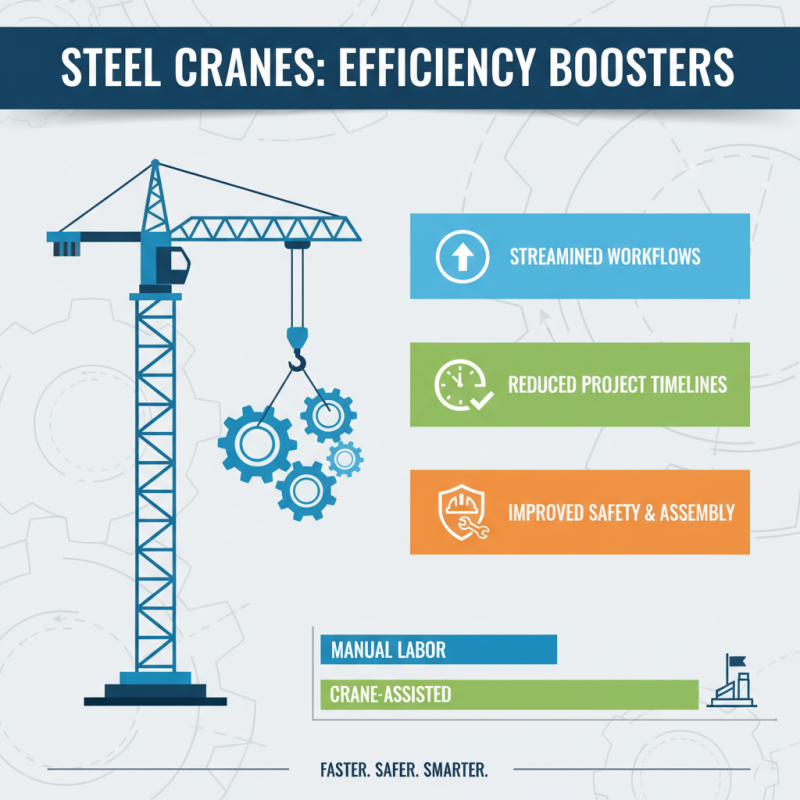

Steel cranes play an integral role in enhancing operational efficiency across various construction and industrial projects. Case studies illustrate how these robust machines streamline workflows and reduce project timelines significantly. For instance, in a major urban construction initiative, the deployment of steel cranes facilitated the swift transportation of heavy materials to elevated structures, minimizing the need for manual labor and decreasing the risk of accidents. This mechanization not only improved safety on-site but also allowed for quicker assembly of critical components, resulting in the project being completed ahead of schedule.

Another example can be found in the manufacturing sector, where steel cranes were utilized to automate the movement of goods within a large facility. By implementing a network of cranes with advanced hoisting capabilities, companies were able to optimize their supply chain logistics. This led to faster production cycles and reduced downtime, enabling manufacturers to keep pace with rising demands. The efficiency gains realized through these steel cranes not only boosted overall productivity but also significantly cut operational costs, underscoring their importance in modern industrial practices.

Steel cranes play a crucial role in construction and industrial projects, but their operation must adhere to stringent safety standards and regulations to ensure the protection of workers and the public. These standards, established by various governing bodies, dictate the design, maintenance, and operation practices required to minimize risks associated with crane use. Operators must be well-trained and certified, and regular inspections of the equipment are mandated to identify any potential hazards before they lead to accidents.

Moreover, safety regulations outline the protocols for load management, including weight limits and load stability, which are vital for preventing accidents during lifting operations. The implementation of safety measures, such as the use of outriggers, effective signaling methods, and personal protective equipment, further enhances workplace safety. By following these regulations, construction and industrial sites can significantly reduce the likelihood of incidents, ensuring that projects proceed smoothly while safeguarding the well-being of all personnel involved.