In the dynamic realm of construction, efficiency and adaptability are paramount. One of the innovative machines that have significantly transformed construction projects is the telescopic crane. These versatile lifting solutions are engineered with an extendable boom that allows for reaching considerable heights and distances, making them indispensable for various construction applications. The telescopic crane’s design facilitates quicker setups and shifts compared to traditional cranes, ultimately contributing to project timelines and productivity.

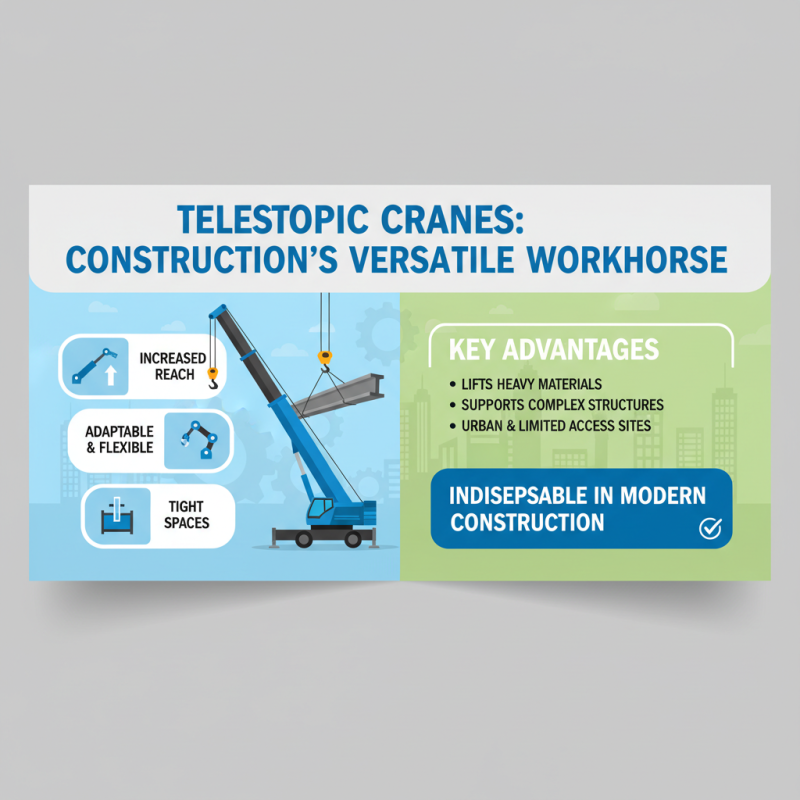

As the construction industry evolves, the demand for equipment that can efficiently navigate complex job sites has increased. Telescopic cranes are uniquely equipped to address this need, providing flexibility in operations ranging from lifting heavy materials to transporting equipment across challenging terrains. With their ability to operate in tight spaces and their capacity to handle substantial loads, the applications of telescopic cranes have expanded immensely, showcasing their vital role in modern construction projects. This article delves into the top ten applications and benefits of telescopic cranes, highlighting their contribution to enhancing construction efficiency and safety.

Telescopic cranes are indispensable in modern building construction projects, serving a variety of functions that enhance efficiency and safety on job sites. Their extendable booms allow operators to reach great heights while maintaining stability, making them ideal for tasks such as lifting heavy materials, placing precast concrete panels, and installing rooftop structures. The flexibility of these cranes provides the ability to navigate tight spaces and access challenging locations, which is essential in urban construction environments where space is often at a premium.

Additionally, the use of telescopic cranes contributes to productivity by facilitating quicker operations. Their rapid setup time enables construction crews to transition between tasks efficiently, minimizing downtime. Furthermore, these cranes can be operated remotely, allowing for enhanced safety as operators can maintain a safe distance from potential hazards on-site. The versatility and maneuverability of telescopic cranes not only streamline the construction process but also help reduce labor costs by allowing fewer workers to manage heavy lifts. This combination of benefits makes telescopic cranes a preferred choice in various phases of building construction, from groundwork to finishing touches.

Telescopic cranes are invaluable assets in heavy lifting operations, primarily due to their versatility and efficiency. These cranes are designed with extendable boom sections that allow them to reach considerable heights and lift heavy loads while maintaining stability. This adaptability makes them ideal for construction projects where space constraints and variable lift requirements are common. By providing the capability to adjust reach dynamically, telescopic cranes significantly reduce the need for multiple cranes on-site, optimizing the workflow and minimizing congestion.

Moreover, the use of telescopic cranes enhances safety in lifting operations. Their design allows operators to maintain a safe distance from the load, reducing the risk of accidents and injuries. Additionally, many modern telescopic cranes are equipped with advanced control systems that improve precision in lifting and placement. This increased control not only protects the equipment and materials but also enhances the overall safety of the work environment. By incorporating telescopic cranes into their operations, construction teams can ensure efficient, safe, and effective lifting solutions for a variety of tasks, from moving prefabricated structures to positioning heavy machinery on-site.

| Application | Description | Benefits |

|---|---|---|

| Construction Sites | Used for lifting heavy materials and equipment on site. | Increases efficiency and reduces manual handling risk. |

| Roofing | Transporting roofing materials to high elevations. | Saves time and enhances safety for roof installation. |

| Bridge Construction | Lifting and positioning heavy bridge components. | Supports precise placement of large structures. |

| Warehouse Operations | Loading and unloading goods in warehouses. | Improves operational efficiency and safety. |

| Telecommunication Installation | Erecting antennas and communication towers. | Allows precise lifting in hard-to-reach locations. |

| Mining Operations | Transporting heavy loads in mining sites. | Enhances productivity by minimizing downtime. |

| Heavy Machinery Installation | Setting up large machines in factories. | Facilitates efficient and safe machinery placement. |

| Demolition Projects | Removing heavy building structures safely. | Reduces risk during the demolition process. |

| Event Setup | Lifting stages and equipment for large events. | Streamlines setup processes for large gatherings. |

| Wind Turbine Installation | Erecting wind turbine components at heights. | Supports renewable energy projects with efficiency. |

Telescopic cranes are increasingly becoming indispensable in the construction industry due to their remarkable versatility. Unlike traditional cranes, telescopic cranes feature extendable arms that allow for greater reach and adaptability to various construction tasks. This flexibility makes them ideal for everything from lifting heavy materials to providing support for complex structures. Their design enables operation in tight spaces where larger cranes cannot maneuver, making them perfect for urban construction projects or job sites with limited access.

When deploying telescopic cranes, it’s essential to understand the specific requirements of your project. One tip is to conduct a thorough site assessment beforehand to determine the crane's required reach and load capacity. This will not only enhance safety but also optimize productivity. Additionally, operators should be well-trained in the crane's operational capabilities to maximize efficiency and minimize risks.

Moreover, the use of telescopic cranes can significantly reduce construction time and labor costs. These cranes often allow for quicker assembly and disassembly as compared to traditional options. A practical tip for project managers is to incorporate a flexible scheduling approach that accommodates the dynamic nature of construction tasks. By aligning crane availability with project phases, teams can enhance workflow and maintain project timelines effectively.

Telescopic cranes have emerged as a pivotal asset in construction projects, particularly in enhancing safety on job sites. Their ability to extend and retract provides operators with remarkable flexibility when positioning loads, allowing for precise movements that minimize the risk of accidents. With an extended range, telescopic cranes can reach elevated areas without the need for scaffolding or other temporary structures, reducing the potential for falls—a leading cause of injuries in construction.

Moreover, the modern design of telescopic cranes often includes advanced safety features such as load moment indicators, anti-collision systems, and outriggers that enhance stability. These features enable operators to make informed decisions in real-time, ensuring loads are lifted safely and securely. By improving visibility and access to hard-to-reach areas, these cranes also reduce the necessity for manual handling, further limiting the chances of worker injury. The synergy of these safety enhancements significantly contributes to a safer working environment, allowing construction projects to proceed with greater efficiency and reduced risk.

Telescopic cranes offer unparalleled cost-effectiveness in construction project management, making them a preferred choice for many construction professionals. According to a report by the Global Construction and Equipment Market Insights, the use of telescopic cranes has been associated with a reduction in operational costs by up to 20% compared to traditional cranes. This reduction can be attributed to their ability to extend reach while minimizing setup times and labor costs, leading to increased productivity on job sites.

Moreover, telescopic cranes excel in versatility, enabling them to handle a wide range of lifting tasks across numerous construction applications—from urban buildings to large-scale infrastructure projects. A study by the American Society of Civil Engineers highlights that construction projects utilizing telescopic cranes are completed an average of 15% faster than those relying solely on conventional lifting equipment. This time savings directly translates into lower labor costs and less overhead, reinforcing the financial advantages of incorporating telescopic cranes in project planning and execution.

Additionally, the longevity and lower maintenance expenses associated with telescopic cranes further enhance their cost-effectiveness. According to a report from the International Construction Equipment Association, cranes that are regularly maintained and used within their operational parameters can deliver a return on investment (ROI) of up to 30% over their lifespan. By minimizing downtime and maximizing efficiency, telescopic cranes not only contribute to cost savings but also improve overall project timelines and resource management.